Fasteners and Machining: Optimizing Layout for Superior Manufacturing

Fasteners and Machining: Optimizing Layout for Superior Manufacturing

Blog Article

Navigating the Globe of Fasteners and Machining: Methods for Accuracy and Rate

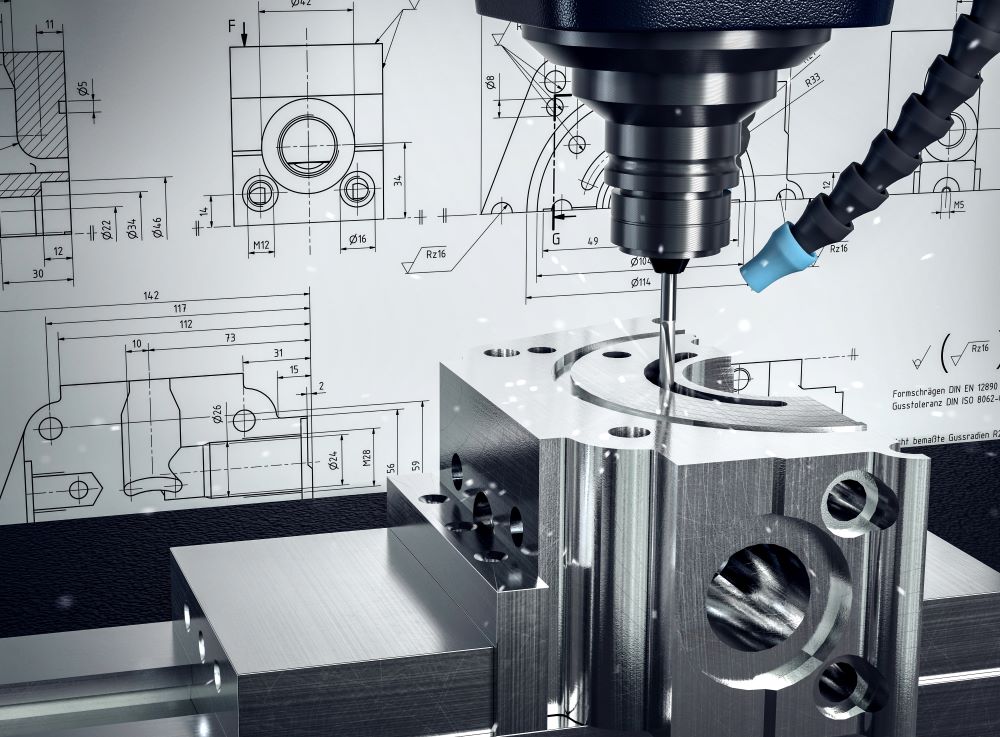

In the complex realm of fasteners and machining, the pursuit for accuracy and rate is a continuous difficulty that demands careful focus to information and strategic planning. From comprehending the varied array of fastener kinds to selecting ideal products that can withstand strenuous needs, each action in the process plays a crucial duty in achieving the desired outcome. Accuracy machining methods additionally boost the complexity of this craft, calling for a fragile balance between technological proficiency and ingenious strategies. As we dive right into the approaches that can enhance both rate and effectiveness in this domain name, the interplay between quality assurance procedures and functional excellence arises as a critical centerpiece.

Understanding Bolt Kind

When choosing bolts for a project, understanding the different types available is vital for making sure ideal efficiency and integrity. Fasteners come in a large variety of kinds, each developed for certain applications and requirements. Bolts are utilized with nuts to hold materials with each other, while screws are functional fasteners that can be used with or without a nut, depending on the application. Nuts, on the various other hand, are internally threaded bolts that companion with bolts or screws, offering a protected hold. Washers are vital for dispersing the lots of the fastener and avoiding damages to the product being secured. Furthermore, rivets are long-term fasteners that are perfect for applications where disassembly is not required. Recognizing the distinctions between these fastener types is crucial for choosing the right one for the job, making sure that the connection is solid, resilient, and trusted. By picking the ideal fastener type, you can enhance the efficiency and long life of your job - Fasteners and Machining.

Picking the Right Products

Recognizing the importance of selecting the right materials is paramount in making sure the optimum performance and integrity of the chosen bolt types reviewed formerly. When it concerns fasteners and machining applications, the material choice plays an essential role in identifying the general stamina, longevity, rust resistance, and compatibility with the desired atmosphere. Different products offer varying buildings that can significantly affect the efficiency of the bolts.

Common materials made use of for fasteners consist of steel, stainless-steel, titanium, brass, and aluminum, each having its distinct staminas and weak points. Steel is renowned for its high toughness and durability, making it ideal for a variety of applications. Stainless-steel uses superb corrosion resistance, suitable for settings vulnerable to moisture and chemicals. Aluminum is lightweight and corrosion-resistant, making it appropriate for applications where weight reduction is crucial. Brass is usually selected for its aesthetic allure and outstanding conductivity. Titanium is understood for its extraordinary strength-to-weight ratio, making it optimal for high-performance applications. Selecting the right product includes taking into consideration aspects such as stamina needs, ecological conditions, and budget plan restraints to make certain the desired efficiency and longevity of the bolts.

Precision Machining Techniques

Along with CNC machining, various other precision techniques like grinding, transforming, milling, and boring play vital functions in fastener manufacturing. Grinding aids accomplish great surface finishes and limited dimensional resistances, while turning is usually utilized to create round components with accurate sizes. Milling and drilling procedures are necessary for shaping and producing openings in fasteners, guaranteeing they fulfill specific specifications and function appropriately.

Enhancing Speed and Effectiveness

To enhance fastener production processes, it is important to enhance procedures and carry out reliable approaches that match accuracy machining techniques. One key strategy for enhancing speed and have a peek at this site effectiveness is the implementation of lean production concepts. By decreasing waste and focusing on continuous improvement, lean practices help optimize and remove bottlenecks process. Additionally, buying automation modern technologies can substantially enhance manufacturing speed. Automated systems can deal with repeated tasks with precision and rate, allowing workers to concentrate on more facility and value-added tasks. Adopting Just-In-Time (JIT) inventory administration can additionally boost effectiveness by making certain that the ideal products are readily available at the correct time, reducing excess stock and decreasing preparations. Cultivating a society of partnership and interaction amongst group members can improve general performance by promoting transparency, analytical, and innovation. By combining these methods, suppliers can achieve an equilibrium in between speed and precision, eventually improving their one-upmanship in the bolt market.

Quality Control Measures

Carrying out strenuous quality control procedures is crucial in guaranteeing the reliability and consistency of fastener items in the manufacturing process. Fasteners and Machining. Quality control steps include different phases, starting from the option of raw materials to the final inspection of the finished bolts. This involves assessing elements such as product toughness, structure, and durability to assure that the bolts meet sector standards.

Routine calibration of equipment and machinery is essential to keep consistency in production and make sure that bolts meet the needed tolerances. Carrying out rigorous protocols for determining and attending to issues or non-conformities is crucial in protecting against substandard items from getting in the market. By establishing a comprehensive quality assurance structure, manufacturers can promote the track record of their brand name and supply fasteners that fulfill the greatest criteria of efficiency and toughness.

Final Thought

In the elaborate realm of fasteners and machining, the mission for precision and rate is a perpetual challenge that requires precise attention to detail and strategic preparation. When it comes to fasteners and machining applications, the product option plays an important duty in identifying the general stamina, toughness, deterioration resistance, and compatibility with the designated atmosphere. Accuracy machining includes various sophisticated techniques that make certain the tight resistances and requirements required for bolts.In enhancement to CNC machining, various other precision methods like grinding, turning, why not look here milling, and drilling play essential functions in bolt production.To enhance fastener manufacturing processes, it this content is essential to streamline operations and apply reliable methods that enhance accuracy machining techniques.

Report this page